Ⅰ Summary

ZSSW-ES series pneumatic cutting butterfly valve consists of single action actuator, butterfly valve, 2/5way solenoid valve, limit switch box and so on. The cylinder of actuator is spring to close or open. That means the valve is automatic to open or close with the spring function inner the cylinder when there is no air pressure. For considering the safe operating and protecting the valve’s quality, the single action actuator is used for the control loop in some special production link. Therefore, it is not often used for the control loop in the general link. It is received the outputting ON/OFF signals from controlling system and other control equipments. Then, the solenoid valve is operating and switching the air channel to driving the piston in the cylinder of actuator. Therefore, the connecting rod box is operated by the piston making the traveling of the piston stem changed from linear rotation to the 0-90°angular displacement. At the same time, the stem is running that make the valve open or closed, which has finished the two ways controlling. It is used for process controlling in the lots of industry areas, such as pulp paper, food, medicament, metallurgy, petroleum and chemistry, electric power, building industries and so on. The butterfly valve has a new structure that it adopts the three-acentric and multistrata sealing.

Ⅱ Main parameters and performance

◆Nominal pressure:

1.6Mpa;2.5Mpa;4.0Mpa

◆Working temperature:-20℃-150℃

◆Leakage: GB/T7213-2005Ⅳ

◆Air supply pressure: 0.4Mpa~0.6Mpa

◆Control voltage: 24VDC/220VAC

Ⅲ Ordering demands;

1. When to make the order, please choose the correct model referring to the item Ⅳ in the table. If not, you’d better provide the following information, such as the type, pressure, dimension, seal type, the main material, medium temperature, the control voltage of solenoid valve and others. The action type is formally air to open. If not, you could note it, including the special demands, such as in the anti-explosion area.

2. The choosing accessories;

Limit switches: 1) Contacted switches 2) Induction switches (24VDC/220VAC)

The material of connecting flanges;

1) A3(Carbon steel) 2) 304SS

Ⅳ The compiling specification of series products’ model;

|

Item

|

1

|

2

|

3

|

4

|

|

5

|

6

|

7

|

8

|

9

|

10

|

11

|

12

|

13

|

Explain

|

|

Z

|

S

|

|

R

|

—

|

|

|

|

|

|

|

|

|

|

|

1

|

Z

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Final controlling element symbol

|

|

2

|

|

S

|

|

|

|

|

|

|

|

|

|

|

|

|

Pneumatic piston actuator

|

|

3

|

Cylinder installing type

|

S

|

|

|

|

|

|

|

|

|

|

|

|

Upright installing

|

|

H

|

|

|

|

|

|

|

|

|

|

|

|

Horizontal installing

|

|

4

|

Plug structure

|

W

|

—

|

|

|

|

|

|

|

|

|

|

Butterfly-type

|

|

5

|

Nominal pressure

|

6

|

|

|

|

|

|

|

|

|

0.6Mpa

|

|

10

|

|

|

|

|

|

|

|

|

1.0Mpa

|

|

16

|

|

|

|

|

|

|

|

|

1.6Mpa

|

|

6

|

Control type

|

E

|

|

|

|

|

|

|

|

Cutting type

|

|

6

|

Cylinder action type

|

S

|

|

|

|

|

|

|

|

Single action cylinder

|

|

7

|

Action type

|

B

|

|

|

|

|

|

|

Air to close

|

|

K

|

|

|

|

|

|

|

Air to open

|

|

7

|

Valve’s state with failure action

|

O

|

|

|

|

|

|

|

Open fully

|

|

C

|

|

|

|

|

|

|

Close fully

|

|

8

|

Nominal diameter DN(mm)

|

50

~

800

|

|

|

|

|

|

50、65、80、100、125、150、200、250、300、350、400、450、500

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9

|

Seat type

|

M

|

|

|

|

|

Multistrata sealing seat

|

|

R

|

|

|

|

|

Teflon soft seat

|

|

10

|

Valve body material

|

P

|

|

|

|

CF8

|

|

M

|

|

|

|

CF8M

|

|

L

|

|

|

|

CF3M

|

|

11

|

Input signal range

|

D3

|

|

|

220VAC

|

|

D4

|

|

|

24VDC

|

|

12

|

Position limit switch

|

A

|

|

Contacted switch

|

|

B

|

|

Induction switches(24VDC)

|

|

C

|

|

Induction switches(220VAC)

|

|

13

|

Name of manufacture

|

LP

|

Zhejiang Tongpu automatic control equipment CO., LTD.

(Wenzhou Lipu automatic control equipment CO., LTD.)

|

Ⅴ Safety

ⅰ We make sure all the valves is very safe only if the material and pressure accord with the requirements in your order.

ⅱ According to the 4th part in the national standard(GB/T17213-2005/IEC60534-1999) of control valves industry area, it is the examination and testing on duty. We have test and examined the pressure and material following the testing report so that we are sure the safety of valves. The technical demands as followed,

1.Material testing

The physical test and chemical composition of the material for producing control valves accord with the standard of control valve or the concerned requirements in the order.

2.the static pressure testing in the liquid

All the compositions of control valve, even no actuator, which must be finished the static testing in the liquid according to the concerned pressure. i.e. it is tested by 1.5 times to the rating pressure.

Ⅵ Principle of operation

The cutting butterfly valve is made up of pneumatic actuator, butterfly valve body, solenoid valve, and air filter, air channel components, connecting and fastening pieces and so on. It finishes the position controlling from full open to full close by the solenoid valve. Then, the signal (e.g., 24VDC, 220VAC) from the controlling instrument or manual tool operating will control the solenoid valve, which output the signal of air pressure at once to impulse the actuator so that it finishes the position controlling from open to closed by the wheel box to drive the butterfly valve trim.

Ⅶ Installing, usage and maintenance

◆ The position of installing the butterfly valve would be in the place as standing by the building platform 、a walking block ect. in order to having the best watching、adjusting、Operating、maintenance and repairing.

◆The pneumatic butterfly valve may horizontal fix or vertical installing.

◆When to install the valve body, the medium must be flow to in a direction from the arrows on the valve body.

◆You would be added to lube oil in the wheel box of the actuator and the joints for half year at least.

◆The waste materials should be removed before installation of piping systems. Once installed, the position of the valve body must be opened completely to sweep by blowing the wind into a pipeline.

◆There are two screws(M12 ~ M20) on the upper end of the cylinder of the pneumatic actuator and the lower end of the box, which is used for adjusting the position from fully open to fully close.

Ⅷ Storage

Control butterfly valve had better be kept in the room among 5℃-40℃ temp. and ≤90% in the humidity. You’d better make sure there are no corrosive characteristics and other bad components in the air.

Ⅸ Packing and transportation

The packing material must accord with the concerned packing standard and demands. The packing must be intact and whole. It should have the own symbol against rain or dust and how to lay up. You should prevent the strong shaking in order to protecting the packing well in the journey of transportation.

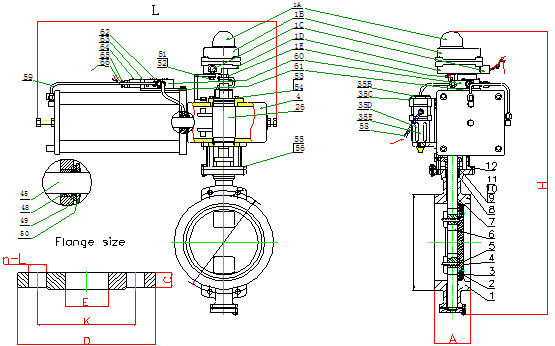

X、ZSSW-ES pneumatic cutting buttering valve(single acting)

1. Valve body 2 Pressure dish 3. Seal ring 4. Butterfly plant

5. Pin 6 stem 7. Bearing 8 Paking

9. Gland 10. Stud 11 Nut 12 Frame

1A.Position of valve show cover 1B.Switch box cap 1C.Switch box connection joint 1D.coreend plate

1E.Switch box retroact shift 4.Box 26.Axle 35B.Air filter nut

35C.Air filter framer 5D.Air filter core 35E.Air filter over coat 45.Piston rod

48.Piston rod gallow sheath 49.Piston rod seal ring 50.Cylinder gallow lid circle nut 51.Switch box and bolt

52.Spring washer 53.Box lid screw 54.Washer 55.Frame bolt

56.Frame bolt spring washer 58.Into air joint 59.Air pipe 60.Solenold valve

61.Solenold valve fix end plate 62.Solenold valve fix screw 63.Solenold valve guilder

64.Solenold valve coil 65 Solenold valve connection joint 66.Solenold valve signal line

|

Nominal

Size

DN

|

Flow

Quotiety

(Kv)

|

Dimension

|

Flange:GB/T9119-2000

|

|

A

|

L

|

H

|

X

|

Valve

N·W

(Kgs)

|

D

|

C

|

K

|

E

|

n-1

|

Flange

N·W

(kgs)

|

|

series:1

|

series:2

|

|

50

|

155

|

43

|

516

|

580

|

100

|

10

|

165

|

20

|

125

|

61.5

|

59

|

4-18

|

2.43

|

|

65

|

165

|

46

|

516

|

595

|

100

|

10

|

185

|

20

|

145

|

77.5

|

78

|

4-18

|

2.97

|

|

80

|

230

|

49

|

516

|

605

|

125

|

10.5

|

200

|

20

|

160

|

90.5

|

91

|

8-18

|

3.23

|

|

100

|

350

|

56

|

516

|

660

|

125

|

12.5

|

220

|

22

|

180

|

116

|

110

|

8-18

|

4.52

|

|

125

|

550

|

64

|

590

|

745

|

160

|

20

|

250

|

22

|

210

|

141.5

|

135

|

8-18

|

4.93

|

|

150

|

780

|

70

|

590

|

765

|

160

|

28

|

285

|

24

|

240

|

170.5

|

161

|

8-22

|

6.53

|

|

200

|

1360

|

71

|

590

|

875

|

160

|

41

|

340

|

26

|

295

|

221.5

|

222

|

12-22

|

9.01

|

|

250

|

2240

|

76

|

590

|

920

|

160

|

69

|

405

|

28

|

355

|

276.5

|

276

|

12-26

|

13.2

|

|

300

|

3160

|

83

|

730

|

1105

|

200

|

99

|

460

|

32

|

410

|

327.5

|

328

|

12-26

|

17.34

|

|

350

|

4120

|

92

|

730

|

1165

|

200

|

143

|

520

|

35

|

470

|

359.5

|

380

|

16-26

|

26.33

|

|

400

|

5430

|

102

|

960

|

1275

|

260

|

161

|

580

|

38

|

525

|

411

|

430

|

16-30

|

33.59

|

|

450

|

6850

|

114

|

960

|

1320

|

260

|

210

|

640

|

42

|

585

|

462

|

484

|

20-30

|

43.86

|

|

500

|

8370

|

127

|

960

|

1385

|

260

|

255

|

715

|

46

|

650

|

513.5

|

534

|

20-33

|

61.07

|

Ⅳ The compiling specification of series products’ model;

|

Item

|

1

|

2

|

3

|

4

|

|

5

|

6

|

7

|

8

|

9

|

10

|

11

|

12

|

13

|

Explain

|

|

Z

|

S

|

|

R

|

—

|

|

|

|

|

|

|

|

|

|

|

1

|

Z

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Final controlling element symbol

|

|

2

|

|

S

|

|

|

|

|

|

|

|

|

|

|

|

|

Pneumatic piston actuator

|

|

3

|

Cylinder installing type

|

S

|

|

|

|

|

|

|

|

|

|

|

|

Upright installing

|

|

H

|

|

|

|

|

|

|

|

|

|

|

|

Horizontal installing

|

|

4

|

Plug structure

|

W

|

—

|

|

|

|

|

|

|

|

|

|

Butterfly-type

|

|

5

|

Nominal pressure

|

6

|

|

|

|

|

|

|

|

|

0.6Mpa

|

|

10

|

|

|

|

|

|

|

|

|

1.0Mpa

|

|

16

|

|

|

|

|

|

|

|

|

1.6Mpa

|

|

6

|

Control type

|

E

|

|

|

|

|

|

|

|

Cutting type

|

|

6

|

Cylinder action type

|

S

|

|

|

|

|

|

|

|

Single action cylinder

|

|

7

|

Action type

|

B

|

|

|

|

|

|

|

Air to close

|

|

K

|

|

|

|

|

|

|

Air to open

|

|

7

|

Valve’s state with failure action

|

O

|

|

|

|

|

|

|

Open fully

|

|

C

|

|

|

|

|

|

|

Close fully

|

|

8

|

Nominal diameter DN(mm)

|

50

~

800

|

|

|

|

|

|

50、65、80、100、125、150、200、250、300、350、400、450、500

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9

|

Seat type

|

M

|

|

|

|

|

Multistrata sealing seat

|

|

R

|

|

|

|

|

Teflon soft seat

|

|

10

|

Valve body material

|

P

|

|

|

|

CF8

|

|

M

|

|

|

|

CF8M

|

|

L

|

|

|

|

CF3M

|

|

11

|

Input signal range

|

D3

|

|

|

220VAC

|

|

D4

|

|

|

24VDC

|

|

12

|

Position limit switch

|

A

|

|

Contacted switch

|

|

B

|

|

Induction switches(24VDC)

|

|

C

|

|

Induction switches(220VAC)

|

|

13

|

Name of manufacture

|

LP

|

Zhejiang Tongpu automatic control equipment CO., LTD.

(Wenzhou Lipu automatic control equipment CO., LTD.)

|

Ⅳ The compiling specification of series products’ model; |